What Is EV Battery Preconditioning and Why Does It Matter?

EV batteries are like humans; we work best in the best environment! Therefore, to get the best out of an EV battery, its environment is crucial to its performance, not just for driving and service life, but also for charging.

What Happens to an EV Battery Before Preconditioning?

Whenever a vehicle is plugged in to charge, the climate of the EV battery is checked before allowing a charge to be applied to it. If the criteria for the EV battery are not within certain parameters, for example, the temperature, humidity, state of charge, or in-balance within the cells itself, then the Battery Management System will need to apply some preconditioning either before charging or during the driving of the vehicle. This could be pre-heating in cold climate conditions or equally cooling in hot climate conditions.

This is achieved either by air, coolant, or air-conditioning. Most Hybrids will have internal batteries located in the cabin area. Full Electric vehicles will have external Batteries, therefore, it is imperative that these systems are checked to maximise their operating performance!

What Challenges come with Preconditioning EV Batteries?

Simple faults like connection problems with busbars, monitoring circuits that give false readings, can cause major problems for HV battery management systems. Careful diagnosis, testing, and reading of Data from the battery management system will help. State-of-Health or more importantly, in-balance of a cell within the battery pack can be a real headache!

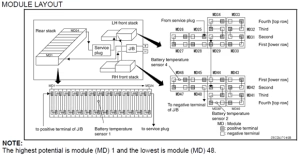

Due to different configurations and construction assembly processes means each HV battery repair can present different challenges, navigating these needs to approaching with not only caution but with good underpinning knowledge and confidence. Simple things, like understanding the orientation of the HV battery busbars to help locate the faulty cell/module, can be a challenge. This can be done with either good manufacturer information (See example below) or manually tracing the route of the electrical connection once access to the HV batteries’ internals has been established. Some manufacturers count their cells from number one from the negative end of the battery; however, some count from the positive end of the battery. As cells/modules don’t have any numbering on them, just this simple misunderstanding could lead to a misidentification of the faulty cell/module and an incorrect attempt at repairing a HV Battery.

EV Battery Module Layout

Swapping cells and/or modules to repair batteries is not simple, and some preconditioning and testing needs to be addressed before a repair to ensure everything meets the HV Battery Management technical criteria.

Learn more about what happens to your EV battery before preconditioning and how it affects performance, range, and fast charging efficiency.

Once a repair has been carried out. Careful testing and analysis should be carried out to ensure that the fix and the battery management system is happy. Only then will the HV battery perform to its full potential.

Therefore, it’s imperative that knowledge of HV Batteries will help to evaluate, maintain, diagnose, and repair HV Batteries safely and competently, and of course, safety throughout the handling of HV batteries with the correct PPE and tools, as they are always live!

To get equipped and qualified, get in contact with us as the leading Training Company on EVs in the UK, by either visiting our website www.pro-moto.co.uk, or calling us on 01252 377762, and start your path to working with Electric Vehicles.

Back To Blogs